By the end of 2012, (and no Apocalyptic events so far) I am trying to put together results of first set of Nano indentation.

As mentioned earlier, 4 specimens from 60°C testing (3 from original mix design + 1 RILEM standard mix design) are used for analyses. Main problem following indentation process is matching mechanical properties to exact locations on specimens. So far success rate of indent attempts are a bit low (around 55-70%). This was mainly due to some last minute revisions on samples and disturbing the flatness of our samples. Yet there are enough data for our purpose. With our new sample holders I believe this rate will raise drastically.

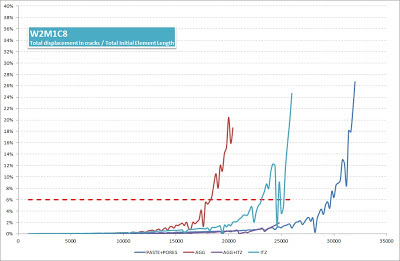

For the last week or so, I have been working on a Matlab code which gathers thousands of indent data, crunches the numbers and groups curves in to several E Modulus values (with 30GPa intervals). I have been working on a standardised way to identify (hypothesise) a way to identify locations of indents. As they are not (or very hardly visible) through light microscope, we needed to randomly distribute a grid on indent area, then check whether it is statistically comparable with NanoIndenter results.

Here is how it works.

\begin{example}

We had original documentation of our samples where interested indent areas are marked.

|

| Micrograph image under stereo microscopy MagX0.63 - Each grid represents 4mm² area |

|

| Micrograph image under stereo microscopy MagX4 - Each cross is placed 200microns from each other as indentation points were |

It is hardly visible from this image but manual point counting is applied on this image where each 200 microns increment is marked digitally. Finally we end up with two images for matching and comparison purposes. First one representing hypothetical distribution of indent points and their corresponding material phases. Second one a representation of how E-modulus values vary through indentation grid.

|

| Point count results |

|

| Surface map diagram of Indent results for E (GPa) values |

This methods allows a standard way to overlay test results with real material properties. This can be further investigated by correlating findings with following subgroups of indent results shown in subplots.

\end{example}

Next set of experiments will start in Jan 3rd 2013. Till then,